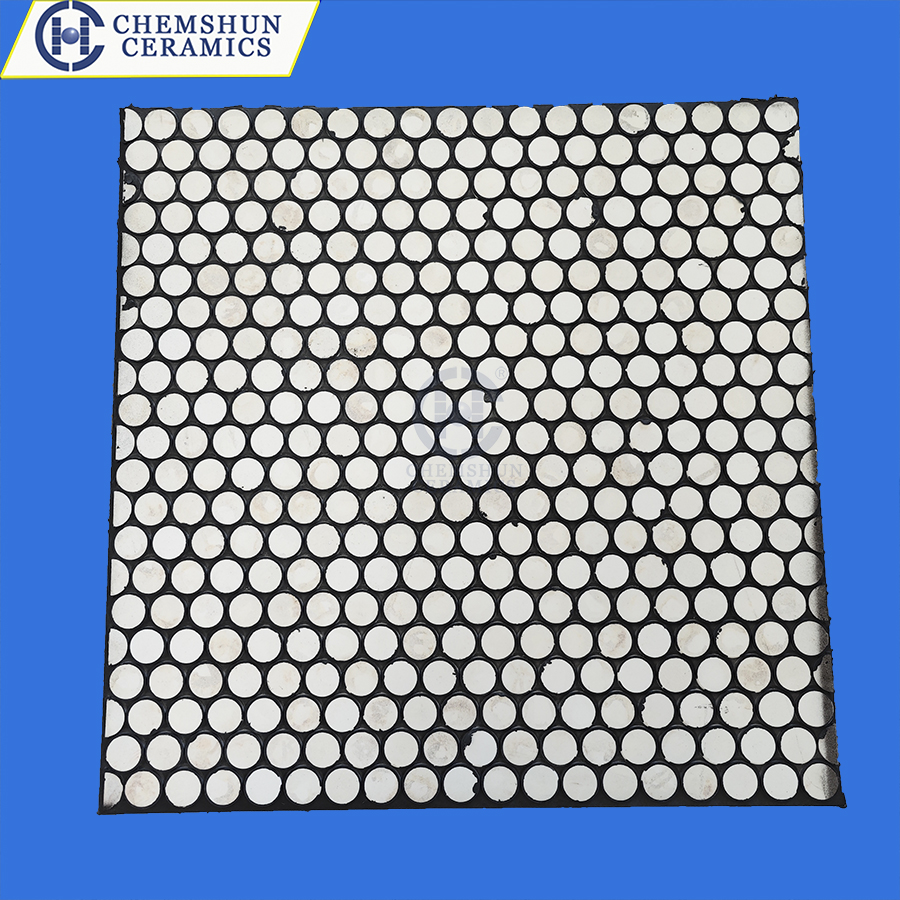

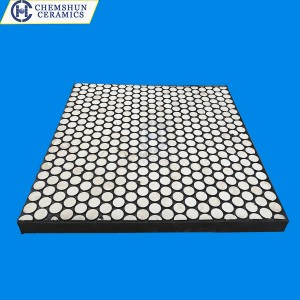

Alumina Silinder Vulcanized salaku Pelat Karét Keramik

Fitur

1) karasa High.

2) lalawanan abrasion punjul.

3) Korosi jeung lalawanan kimiawi.

4) Beurat hampang.

5) Bisa divulkanisasi dina sagala jinis panel karét atanapi conveyor.

Aplikasi dina Industri

| Industri | Sistim parabot | bagian parabot |

| Semén | Sistim pre-blending pikeun nabrak batu kapur jeung suluh atah | Parasut, bunker, katrol katinggaleun, congcot ngaleupaskeun |

| Sistim ngagiling atah | Pakan parasut, cingcin nahan, piring scraper, ring segel, pipa, ember hansip, siklon, awak concentrator bubuk, bunker | |

| Sistim ngagiling semén | Parasut, bunker, roda kipas vane, casing kipas, siklon, saluran sirkular, conveyer | |

| Sistim ball mill | Awak knalpot Pulverizer sareng roda baling-baling, awak konsentrator bubuk, saluran pipa batubara, saluran hawa panas | |

| Sistim sintering | Inlet / outlet ngalipet, plat nilai angin, siklon, parasut, pipa collector lebu urang | |

| Sistim afterheat | Pipa Separator sareng témbok | |

| Baja | Sistim dahar bahan baku | Hopper, silo |

| Sistim Batching | Pergaulan bunker, Pergaulan tong, Pergaulan disk, disk pelletizer | |

| Sistim angkutan bahan Sintered | Hopper, silo | |

| Sistem Dedusting sareng Ash discharge | Pipa dedusting, tikungan, y-sapotong | |

| Sistim coking | Coke hopper | |

| Ngagiling-speed sedeng | Cone, buffles separation, pipa outlet, pipa batubara dipulverized, burner congcot | |

| gilinding bal | Classifier, cyclone separator, bengkok, bubuk concentrator cangkang jero | |

| kakuatan termal | Sistem penanganan batubara | Mesin kabayang LIPI, Hopper batubara, feeder batubara, orifice |

| Sistim ball mill | Pipa pemisah, siku sareng kerucut, siku pabrik batubara sareng tabung lempeng | |

| Ngagiling-speed sedeng | awak ngagiling batubara, separation buffles, congcot, pipa, siku | |

| Ngagiling ragrag | Pipa sareng siku batubara ditumbuk | |

| Sistim dedusting | Pipa Dedusting sareng siku | |

| Sistim ngaleupaskeun lebu | cangkang kipas duster urang, pipa | |

| Palabuhan | Sistem angkutan bahan | Cakram sareng hopper mesin kabayang ember, hopper titik transfer, hopper unloader, |

| Ngalebur | Sistem angkutan bahan | Measuring Hopper, coke hopper, geter screen's chute, head valve, Intermediate bin, buntut bin |

| Sistim Batching | bets Hopper, mesin Pergaulan | |

| Sistim ngaduruk | Ember abu, tabung kalsin pompa, hopper | |

| Sistim dedusting | Pipa Dedusting sareng siku | |

| Kimia | Sistem angkutan bahan | Hopper, silo |

| Sistim dedusting | Pipa Dedusting sareng siku | |

| Parabot ngolah | Vibromill liner | |

| Batubara | Sistem penanganan batubara | Mesin kabayang LIPI, Hopper batubara, feeder batubara |

| Sistem cuci batubara | Hidrosiklon | |

| Pertambangan | Sistem angkutan bahan | Hopper, silo |

Lembar Data Téknis

| S.No. | Atribut | Unit | CHEMSHUN 92 I | CHEMSHUN92 II | CHEMSHUN 95 | CHEMSHUN ZTA |

| 1 | Kandungan alumina | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 2 | Kapadetan | g/cc | ≥3.60 | ≥3.60 | > 3.65 | ≥4.2 |

| 3 | Warna | - | Bodas | Bodas | Bodas | Bodas |

| 4 | Nyerep cai | % | <0.01 | <0.01 | 0 | 0 |

| 5 | Kakuatan Flexural | Mpa | 270 | 300 | 320 | 680 |

| 6 | Kapadetan Moh | Kelas | 9 | 9 | 9 | 9 |

| 7 | Batu Sumur Teu karasa | HRA | 80 | 85 | 87 | 90 |

| 8 | Teu karasa Vickers (HV5) | Kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 9 | Kateguhan Patahan (Min) | MPa.m1/2 | 1000 | 3-4 | 3-4 | 4-5 |

| 10 | Kakuatan compressive | Mpa | 850 | 850 | 870 | 1500 |

| 11 | Koéfisién ékspansi termal (25-1000ºC) | 1×10-6/ºC | 8 | 7.6 | 8.1 | 8.3 |

| 12 | Suhu operasi maksimum | ºC | 1450 | 1450 | 1500 | 1500 |

Kaunggulan keramik Chemshun

1) Tim téknis profésional pikeun nanggung desain CAD.

2) Tim instalasi profésional pikeun mampuh jasa install.

3) prosés well ngadegkeun sakumaha per standar internasional.

4) Nampa ubin standar sareng tos direkayasa.

Tag produk

Tulis pesen anjeun di dieu sareng kirimkeun ka kami